<2023> 단결정(단입자) 양극재 기술개발 동향 및 시장 전망

전기차 배터리 성능을 획기적으로 높일 수 있는 단결정 구조의 양극재 양산을 앞두고, 중국 및 한국의 업체간 경쟁이 본격화될 전망이다.

현재 상용화된 전기차에 적용된 배터리 양극재는 수많은 금속화합물 결정이 모인 다결정 구조이다. 그런데 이러한 양극 물질을 일정 두께로 만드는 압연 공정 및 충방전 과정에서 입자간 균열이 발생하기가 쉽다. 충전과 방전이 반복될수록 소재 사이의 균열이 생겨 틈이 커진다. 균열에

의한 소재의 파괴는 배터리 내 가스발생을 증가시키고, 충방전 사이클을 감소시켜 수명감소로 이어진다.

반면 단결정은 입자가 부서지지 않아 이런 문제가 없다. 또한 용량을

증가시키기 위해 소재내 니켈의 함량을 증가시킴에 따라 구조적인 안정성이 낮아지고 화재 위험성이 높아지고 있어 이에 대한 해결책으로 단결정 양극재의

개발 필요성이 커지고 있다.

단결정 양극재는 또한, 양극재 가공 비용을 낮추고 수율도 개선할 수

있다. 즉, 단결정 양극재는 잔해물이 없어 불량품 발생 확률을

낮추고 수세(washing)공정을 거칠 필요가 없기 때문이다. 수세공정은

양극재를 만들 때 반드시 필요한 공정으로 물로 불순물을 제거하는 과정이다.

단결정 양극재가 상용화되면 하이니켈 양극재 적용도 확대될 전망이다. 또

가스발생이 줄면 그만큼 수명이 증가하고 더 많은 활물질로 내부를 채울 수 있어 에너지밀도를 높일 수 있다. 이를

전기차 배터리 팩에 적용하면 지금보다 더 적은 배터리 셀 개수로 1회 충전으로 500km이상의 주행거리를 달성하고, 롱레인지 모델 등 더 긴 주행거리를

갖춘 차량 라인업을 갖출 수 있게 된다. 즉 원가 절감과 성능 향상을 동시에 잡을 수 있는 게임 체인저가

될 수 있는 이유이다.

그렇다고 단결정 양극재의 장점만 있는 것이 아니고 단점도 있다. 그간에

다결정 양극재 개발에 주력한 이유는 입자가 큰 단결정 소재는 초기 저항값이 높아 원하는대로 전압을 것 수 없었다.

이렇게 되면 제대로 된 출력이 나오지 않아 배터리 성능을 높일 수 없는 단점이 있기 때문이었다.

다만 추가 공정이 필요하고 작동 전압이 커서 배터리 온도가 상승할 수 있다. 또한

전극공정의 일부인 압연공정에서 단결정 입자가 손상될 수 있어서 양산 초기에는 순수한 단결정이 아니라 다결정과 섞어서 생산이 이루어질 것으로 보인다.

이미 중국의 업체들은 NCM523, 622등에서 단결정 양극재를 생산하고

있으며, LG화학, 에코프로비엠, 엘앤에프, 포스코 퓨처엠 등 국내업체들도 대부분 개발을 마치고 고객사에

품질 테스트를 진행하고 있다. 단결정 NCA, NCM이 대상이며, 양산준비를 마친 상태로 볼 수 있다.

업계는 단결정을 만드는 것도 중요하지만, 내구성 확보를 위한 코팅

기술에서 성능과 품질이 판가름 될 것으로 전망한다. 즉 입자크기를 키우면서 표면처리를 어떻게 할 것인지가

핵심이다.

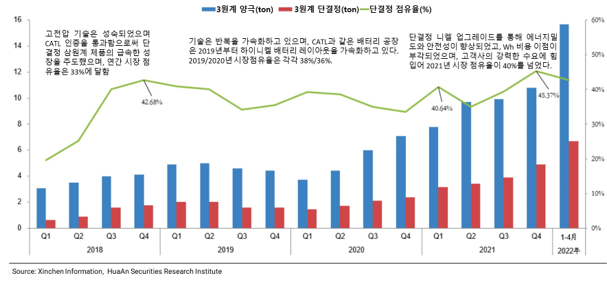

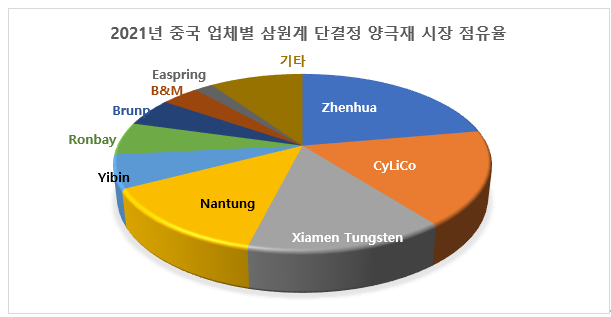

현재, 단결정 양극재의 양산에 의한 시장은 중국의 5대 선두업체가 전체 시장의 75%정도를 차지하고 있는 상황이다.

한국의 각 양극업체의 발표에 의하면 23년 올해부터 샘플제공을 시작으로

25년에는 대략 12만톤 이상을 생산할 것으로 SNE Research는 전망하고 있다. 현재 중국의 삼원계 단결정

양극재의 경우, 60%~70%가 NCM 523등 5 시리즈 단결정 비중이 가장 높으며, NCM622 등 6 시리즈 단결정 비중은 18~ 25% 정도를 차지하고 있으며, Ni함량이 80%이상인 8 시리즈인

경우는 21년부터 생산비중이 증가하여 현재는 약 15%를

점유하고 있는 것으로 나타나 있으며, 이 비중은 계속 증가할 것으로 보인다.

SNE Research의 전망에 따르면, 한국의 경우, Ni함량에 따른 생산량 data가 아직 없어서 현재로선 시장 전망이 어려우나, 중국의 경우, 2025년 Hi-Ni이 약 42억달러, Mid-Ni이 92억달러로 전망되며, 2030년에는 Hi-Ni은 약 240억달러, Mid-Ni은 238억달러로 Hi-Ni의

시장이 더 커질 것으로 전망된다.

본 보고서의 Strong Point

① 단결정 Ni계 양극재개발의 fundamental

및 advances까지 내용 수록

② 단결정 Ni-rich계

양극재에 대한 아주 상세한 연구동향 및 향후 전망 수록

③ 단결정

Ni-rich계 양극의 용량열화 메커니즘 연구에 대한 내용 수록

④ 단결정 NCM 양극재의

주요 합성법에 대한 비교

⑤ 단결정

양극재 업체의 상세한 최근 동향 및 특허 분석

⑥ 단결정 양극재 시장 전망

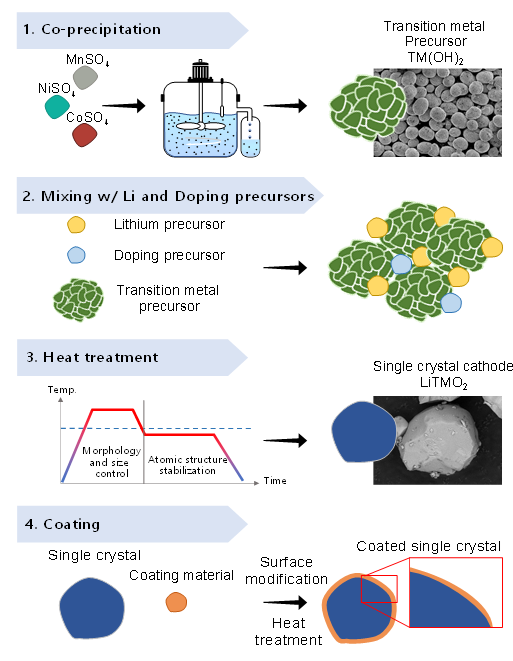

[일반적인 단입자 Ni 계 layered 양극재 합성 및 추가 개질 공정 모식도]

1. 양극재 개요······ 11

1.1. 양극재 개발의 역사·········

11

1.2. 양극재를 둘러싼 최근의 동향·········

12

1.2.1. 층상 산화물 양극재·········

12

1.2.2. 스피넬 산화물 양극재········

13

1.2.3. 폴리음이온 산화물 양극재··········

14

1.3. 양극재별 개발 현황···········

15

1.3.1. 미세구조 변경········ 16

1.3.2. 양극 균열 제거········· 17

1.3.3. One Pot Process 적용············ 18

1.3.4. 전자레인지 처리·············· 19

2. 단결정 Ni-rich계 layered 양극재의 연구동향 및 향후 전망·········

20

2.1. 단결정 Ni-rich layered 소재

연구 필요성············

21

2.1.1. Ni-rich layered소재의

필요한 이유 (장점)············ 21

2.1.2. Ni계 layered 양극소재 열화 메커니즘··········

24

2.1.3. Ni계 layered 양극소재 단결정화 (단입자화) 필요성········· 27

2.2. 단결정 양극재 정의···················

28

2.3. 단결정 양극재 기술 개발 현황·················

28

2.3.1 단입자 Ni계 layered 소재 합성 연구···············

29

2.3.2 단입자 Ni계 layered 소재 합성위한 소결 방법 연구······

35

2.3.3. 단입자 Ni계 layered 소재 성능 개선위한 소재 개질 연구······ 42

2.3.3.1 표면 코팅 연구····················

42

2.3.3.2. 원소 치환 연구 (도핑)·····················

45

2.3.3.2.1. 단일 도핑·······················

46

2.3.3.2.2. 듀얼 도핑·················

48

2.3.3.3. 전해액 최적화 연구····················

48

2.3.4. 단입자 Ni계 layered 소재 활용 방안················

49

2.3.4.1. Ni계 layered 소재 단입자화 전극 설계 관점에서 장점····· 50

2.3.4.2. Ni계 layered 소재 단입자화 전극 설계 관점에서 단점···· 51

2.3.4.3. Ni계 layered 소재 단입자화 문제점 해결 위한 연구······ 52

2.4. 소재 단입자를 통한 개선점····················

53

2.4.1. 입자 깨어짐 특성 완화······················

53

2.4.4.1. 전극 제작 공정에서의

프레스 단계··················

53

2.4.2. 충방전 과정에서의 입자

깨어짐··························

53

2.4.3. 비표면적 감소를 통한 표면

열화의 양적인 감소···············

54

2.4.4. 에너지 밀도 증가·················

56

2.4.5. 수세공정 생략 가능················

57

2.5. 현 단결정 양극재 기술 개발 한계 및 해결 위한 연구··· 58

2.5.1. 합성 조건 최적화의 어려움으로

인한 소재 결정 구조의 열화······ 58

2.5.2. 입자 사이즈 한계························

60

3. 단결정 Ni계 양극재 개발: Fundamental 및 advances···························

62

3.1. 개요····························

62

3.2. Ni계 양극재···························

64

3.2.1. 화학구조·······························

64

3.2.2. 전자구조···················

66

3.3. Ni계 층상 산화물의 과제················

67

3.3.1.

합성의 어려움······················

67

3.3.2. 구조적 불안정성··························

70

3.3.3. 화학적 불안정성··························

71

3.3.4. 기계적 성능 저하························

74

3.3.5. 안전성 문제····························

76

3.4. 단결정 Ni계 층상 산화물의 유래····························

77

3.5. 단결정 Ni계 층상 산화물의 합성····························

82

3.5.1. 합성 방법··································

82

3.6. 단결정과 다결정 재료의 비교

연구······················

93

3.7. 단결정 Ni기반 양극재의 최신 공정·························

96

3.7.1. 도핑과 표면 코팅·························

96

3.7.2. 기계적 연구··························

97

3.8. 결과 및 결론························

101

4. 단결정 Ni-rich NCM 양극의 용량열화 메커니즘 연구················· 102

4.1. 개요·····································

102

4.2. Ni-rich 단결정, 다결정 양극의 기본특성 평가 ························ 103

4.2.1. 단결정, 다결정 양극재 합성·······························

104

4.2.2. 단결정, 다결정 양극재 조성 및 분석·····················

105

4.2.3. 단결정, 다결정 양극재의 전기화학적 특성······················

107

4.2.4. 단결정, 다결정 양극재의 구조적 응력분석·················

110

4.2.5. 단결정, 다결정 양극재의 in-situ XRD 분석··························

113

4.2.6. 단결정, 다결정 양극재의 TEM 분석···························

116

4.2.7. 결과 및 결론·································

118

5. 단결정 Ni-rich 양극재의 입자제어 (소결 조제 적용)··························

119

5.1. 개요··································

119

5.2. 실험에 대한 설명·······························

120

5.3. 실험 결과·········································

120

5.3.1. 결정성장 촉진을

위한 소결 조제의 최적화·······················

120

5.3.2. 결정성장 메카니즘·········································

121

5.3.3. Ni-rich 단결정

양극의 구조···································

123

5.3.4. Ni-rich 단결정

양극의 성능································

127

5.4. 소결 조제의 적용 결과·····································

133

6. 단결정 NCM 양극재의 올 건식 합성법(All Dry Synthesis)·······················

134

6.1. 개요··········································

134

6.2. 건식 합성····················· 137

6.3. 건식 합성 결과 및 논의······················

138

6.3.1. 전구체 구조 및

형태····························

138

6.3.2. NCM 형성에

대한 소결 조건의 영향··················

140

6.3.3. 볼 밀링 전구체의 단결정

NCM···················

143

6.3.4. 결론·····································

147

7. 단결정 NCM523 양극재의 One Spot Synthesis·······················

148

7.1. 개요···········································

148

7.2. NCM523의 합성····························

150

7.3. 재료의 특성화(Characterization)···················

150

7.4. 전기화학적 특성·························

151

7.5. 실험결과 및 논의······················

151

7.5.1. 양극재 합성 결과물 분석··························

151

7.5.2. 양극재의 전기화학적 특성···················

156

7.5.3. 결론·······················

158

8. 단결정 NCM 양극재의 합성 및 개질(modification)··············

160

8.1. 개요·······························

160

8.2. 성장 메커니즘(NCM양극에 대한 고려사항)················

161

8.3. Solid state 반응···························

162

8.4. 고체-액체 유변학적 반응·······················

163

8.5. 용융염 Flux에서의 결정 성장··························

165

8.6. Modification of morphology························

166

8.6.1. 모양 제어························

166

8.6.2. Facet의 조절··································

167

8.6.3. 결론·····························

168

9. 단결정 양극재 개발: DOE Program·································

169

9.1. Ni-rich 단결정 양극재의

초고속 수열법에 의한 생산·····················

169

9.2. Ni-rich 고성능 단결정

양극재의 scale-up (advanced Salt적용)············· 174

9.3. 고성능 전고체 LIB를 구현하는 단결정 양극재················

176

10. 단결정 양극재 업체 특허

분석····························

180

10.1. Tesla··························

180

10.2. LG Chem································

183

10.3. SM Lab···························

188

10.4. Nano One Materials·······························

192

10.5. 포스코 퓨처엠·························

196

10.6. 코스모 신소재·································

200

10.7. 엘엔에프························

206

10.8. Easpring··································

209

10.9. BASF Shan Shan·······································

211

10.10. GEM······································

214

10.11. XTC (Xiamen Tungsten)·················

217

10.12. Henan Kelong·····························

221

10.13. 현대/기아자동차·························

224

10.14. 6K Inc.····························

226

10.15. Dynanonic····················

229

10.16. Suzhou Long Power··························

231

10.17. Fengchao Energy·····························

235

10.18. Ecopro BM··························

238

10.19. Umicore·······································

240

11. 단결정 양극재 업체 동향·························

243

11.1. LG Chem·······························

251

11.2. 포스코 퓨처엠··························

253

11.3. 에코프로비엠·····························

257

11.4. Zhenhua E-Chem(ZEC)·····················

258

11.5. Chanyuan Lico···················

264

11.6. Ronbay··················

270

11.7. XTC (Xiamen

Tungsten)·······················

276

11.8. Tianjin B&M················

281

11.9. Easpring···························

286

11.10. Reshane·····················

294

11.11. Yibin Libode················

298

11.12. Wanxing 123··················

301

11.13. GEM·····················

305

12. 단결정 양극재 시장 전망····························

313

12-1. 2017~2022H1 중국

단결정 생산량·························

317

12-2. 2019~2022.04 중국

단결정 생산량과 양극재에서의 비중····································

318

12-3. 2019~2022Q1 중국의

삼원계 단결정 양극재별 생산량 분포······························

318

12-4. 2019~2022Q1 중국의

삼원계 단결정 양극재별 생산량 비중······························

319

12-5. 2019~2022Q1 중국의

삼원계 단결정 양극재별 시장 침투율······························

319

12-6. 2021년 중국 업체별 삼원계

양극재 시장 점유율··························

320

12-7. 2021년 중국 삼원계 단결정

양극재 업체별 생산량 및 점유율·························· 320

12-8. 한국-중국 삼원계 단결정 생산량 전망··································

321

12-9. 한국 삼원계 단결정 양극재

시장 전망································

321

12-10. 중국 삼원계 양극재 중

단결정 양극재의 사용 비율···········································

322

12-11. 중국 삼원계 단결정 양극재별

생산량 비중 전망·················································

322

12-12. 중국 삼원계 단결정 양극재별

생산량 시장 전망·················································

323

References·····································

323